Elevator pitch

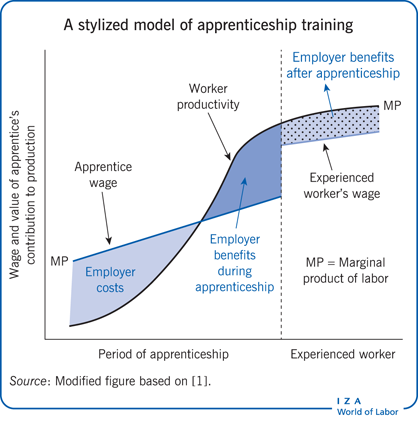

Economists once believed firms do not pay to develop occupational skills that workers could use in other, often competing, firms. Researchers now recognize that most firms benefit from investing in apprenticeship training. Evidence indicates that financial returns to firms vary. Some recoup their investment within the apprenticeship period, while others see their investment pay off only after accounting for reduced turnover, recruitment, and initial training costs. Generally, the first year of apprenticeships involves significant costs, but subsequently, the apprentice’s contributions exceed his/her wages and supervisory costs. Most participating firms view apprenticeships as offering certainty that all workers have the same high level of expertise and ensuring a supply of well-trained workers during sudden increases in demand and to fill leadership positions.

Key findings

Pros

The apprentice’s contribution to production is large enough to offset most costs to firms.

By retaining most apprentices, firms benefit substantially from low recruitment and training costs.

Knowing that all trained apprentices have mastered a common set of skills is valuable to firms.

Apprenticeship training enhances subsequent innovation within the training firm.

Treating apprenticeship expenses as capital investments would improve measured gains.

Cons

Most firms in advanced economies do not offer apprenticeships.

Firms perceive weak returns because they fear trained apprentices will be hired away by other firms.

Some estimates show firms recover only modest parts of their investment during the training period.

Quantitative estimates of gains for employers are uncertain, based on only a few studies.

It is difficult for firms to assess the long-term benefits of apprenticeship investments.

Author's main message

Apprenticeship training is usually a profitable investment for firms as well as workers. Often, firms can recoup all or most of their costs within the apprenticeship period. By providing firms with information on economic returns, by helping them set up apprenticeships, and by funding off-site training, policymakers can promote the expansion of effective career training and increased worker earnings with only modest public expenditures.

Motivation

Policymakers are searching for ways to deal with the erosion of middle-class jobs and a level of youth joblessness that has reached a post-1950s high. The International Labour Organization sees a worsening youth employment crisis that could lead to a “scarred” generation facing long periods of unemployment and weak earnings prospects. The Organisation for Economic Co-operation and Development (OECD) considers youth unemployment in developed economies severe enough to require government subsidies for hiring.

Meanwhile, the earnings of workers in middle-wage occupations have been declining relative to low-wage and high-wage employment in many advanced economies. Yet employers in a variety of industries are complaining about a mismatch between the skills that they want and the skills that job applicants actually possess. Given the success that countries with robust apprenticeship systems have had in reducing youth unemployment, raising the status of middle-wage jobs, and limiting skill shortages, the OECD and the EU have called for major expansions of these programs. This paper examines one barrier to this expansion (the perceived high net costs to firms) and offers empirical evidence that firms typically reap positive net benefits from well-structured apprenticeship programs (see Variations in scope and scale of apprenticeships).

Discussion of pros and cons

Theories related to apprenticeship training

Like investments in plant and equipment, increasing workers’ skills requires spending today to generate a flow of returns of enhanced productivity in the future. While additional firm-specific skills raise a worker’s productivity only within the firm that provides the training, additional general skills can increase productivity in a range of firms. Labor economists have theorized that firms are likely to pay only to develop workers’ specific skills, since the gains from general skills will accrue to the worker through higher wages from the training firm or some other firm.

Amendments to this theory, however, suggest that employers do have an incentive to finance general training. Partly, this is because it is costly for workers to quit and for employers to replace them. Also, firms providing the training know more than other firms about the content and value of training and how well individual workers have absorbed the knowledge. Furthermore, specific and general skills are often complementary: The more general skills a worker possesses (including occupational skills), the more productive that worker is likely to be after acquiring firm-specific skills.

Skills rarely raise productivity in isolation, however. Increases in productivity typically result when workers use their skills to complement the work of others within the organization. Economic theories have offered useful conceptual frameworks, but determining whether firms actually benefit from apprenticeship investments requires empirical estimates.

Costs and benefits to firms

Employers’ net costs depend on a variety of factors:

the mix of classroom and work-based training provided;

occupation;

skill;

wage progression; and

the productivity of the apprentice while learning to master the required skill [2].

Direct costs include apprentice wages, the wages of trainer specialists for the time they oversee apprentices, and the costs of materials and additional space required for the apprenticeship. The benefits depend on the extent to which the apprenticeship saves on subsequent hiring and training costs, lowers turnover costs, and enhances productivity more than added wage costs [1].

Also valuable is employers’ increased certainty that apprenticeship graduates know all the relevant occupational and firm-specific skills, and can work well alongside other skilled workers. In addition, having extra well-trained workers, such as apprentice graduates, provides firms with valuable options for expanding production without reducing quality in response to uncertain demand shocks, and for covering unexpected absences of skilled workers [2]. The high level of occupational mastery achieved by apprentices may also increase the pace of innovation and the ease of implementing new technologies.

It would take years, if not decades, to track all the costs and benefits of apprenticeships in a large sample of employers and countries. Studies have not been able to quantify all the benefits that accrue to employers for many years after the apprenticeship. But several studies estimate the net costs and benefits during and soon after the apprenticeships.

Estimated net costs of apprenticeships differ greatly

The most extensive studies of the net costs of apprenticeship programs have focused on German and Swiss firms. An analysis of data from surveys of 1,825 German firms and 1,471 Swiss firms identifies the wages of trainers and the wages of apprentices as the main gross costs of apprenticeship programs borne by employers [3]. The study offers details on the wages of management and training personnel, wages of regular skilled and unskilled workers, wage costs of apprentices, time at the workplace, share of apprentices’ workplace time devoted to tasks normally undertaken by unskilled and skilled workers, and the relative productivity of apprentices compared with regular workers.

Apprenticeships differ greatly in costs as well as in the share of salaries offset by their contribution to production. On average, the gross costs per annum amounted to €15,500 for German firms and about €18,000 for Swiss firms. Although Swiss firms spend more than German firms, they derive substantially higher benefits from the value added by apprentices. Swiss firms gain more than €19,000 a year, more than double the €8,000 in benefits that German firms attribute to the value of production generated by apprentices. For a three-year apprenticeship, Swiss firms are thus able to recoup the €54,400 cost with benefits of €57,100, while German firms experience a €46,600 cost but realize only €24,000 in benefits [4].

Why do Swiss firms—where the wages of management, skilled, and unskilled workers, and even apprentices are generally higher than in German firms—show a small net benefit, while for the average German firm costs exceed benefits? Higher Swiss costs are offset by substantially higher returns for several reasons. First, apprentices are at work for more days in Switzerland than in Germany [4]. Over the course of a three-year apprenticeship, Swiss apprentices are at work an average of 468 days, compared with 415 for their German counterparts. Second, when in the workplaces, Swiss apprentices devote an average of 83% of their time to productive tasks, compared with only 57% for German apprentices, who engage more in practicing tasks and in coursework [3], [4]. Third, the differences in time spent on tasks with no direct value to the firm are substantial. In Switzerland, apprentices allocate only 13–21% of their time on these tasks, while in Germany these tasks take up 31–57% of the time [2].

One striking feature of apprenticeship programs in both countries is how quickly apprentices advance through their training and move from unskilled to skilled tasks. In Switzerland, the productivity of apprentices rises from 37% of a skilled worker’s level in the first year to 75% in the third (final) year [3]. The increase in Germany is just as rapid, increasing from 30% to 68% of a skilled worker’s productivity over the apprenticeship period [3]. Thus, in both countries, apprentices accumulate substantial and similar levels of human capital. Still, nearly all German firms with apprenticeships (93%) incur net costs, while a majority of Swiss firms (60%) more than recoup their costs [4].

Are the higher in-program net costs to German firms offset by any advantages after the apprenticeship period? Apparently yes, at least for one key outcome—the retention of apprentices within the firm. In Switzerland, only about 36% of apprentices remain with the firm that provided the apprenticeship training. In the former West Germany, the corresponding figure was 64% [4]. Thus, while German firms bear much higher net costs than Swiss firms during the apprenticeship period, they are more likely to recoup these costs over time by retaining the workers they have trained. One reason for this is the higher degree of regulation in Germany than in Switzerland [5]. German unions are stronger, laying off workers is more difficult, and German works councils do more to influence the training of young workers.

Still, not all recent studies indicate that German firms actually experience higher net costs for their apprenticeship investments. For example, one study finds that, for many occupations, the gains to German firms during the apprenticeship period more than offset the costs [5]. That conclusion is drawn by estimating the impact of apprenticeships on company profits. For apprenticeships in trade, commercial, craft, and construction occupations, these estimates show a positive impact on profits. However, in manufacturing, the effect on current profits is negative, indicating a positive net cost [2].

Another careful study of apprenticeships in a sample of 100 German firms also finds that the majority of firms recoup their investments during the training period [6]. This study used a tool called QEK (for “quality, returns, and costs”) that allowed employers to make a detailed assessment of the costs and benefits of apprenticeship during the training period. QEK records gross costs based on an approach used by the Federal Institute for Vocational Education. The costs include staff costs of trainees, training allowances, social security contributions, the wages of full-time and part-time trainers, the cost of space and materials, certification fees, and administrative costs.

According to the study, most firms experience low net costs or even net benefits from sponsoring apprenticeships. However, the net costs vary widely, some firms gaining more than €10,000 and others experiencing net costs. Somewhat surprisingly, net costs are inversely related to the quality of the apprenticeship. High-quality apprenticeships have higher gross costs, but they are also much more likely to help employers recoup their investment during the training period [6].

Older studies were considerably less optimistic about the net costs of apprenticeship investments in Germany. According to one, an apprentice’s contribution to production accounted for only about 40% of company expenditures on training [7]. Moreover, the direct post-program benefits may not be high enough for the employer to recoup its investments. Although this study is worth noting, more recent and in-depth analyses indicate larger productivity contributions by apprentices—especially in the period following the apprenticeship.

Detailed estimates of gains to employers from apprenticeship investments are less common outside Germany and Switzerland. An extensive study of Canadian employers sponsored by the Canadian Apprenticeship Forum (2006) estimated employer costs and benefits of apprenticeships in 15 occupations [8]. The study drew on responses from 433 employers, with at least 16 per occupation. All were four-year apprenticeships. The average gross costs ranged from about C$78,000 for cooks to C$275,000 for construction electricians. Average in-program benefits—measured as the revenue generated by the apprentices—varied widely as well, ranging from C$120,000 for cooks to C$338,000 for construction electricians. For all 15 occupations, employers earned a positive return on their apprenticeship investments during the training period. The average benefit was 1.38 times the average cost. Any post-program benefits would add to the economic returns.

A recent analysis of apprenticeships in the UK examined the returns to eight employers in each of four industries—engineering, construction, retail, and business administration [1]. Training ranged from 18 months for basic credentials to two to four years for advanced apprenticeship programs. Average gross costs were higher than the average benefits during the apprenticeship period in all four industries, magnitudes varying widely by industry. Apprenticeships were most costly in engineering and construction despite the fact that the productive contributions of the apprentices covered were worth about 50% of a fully qualified worker’s wage. The dollar value of an apprentice’s contribution to output is high but so are their wages. Still, the authors estimate that employers in all four industries at least break even and begin earning positive returns during the early post-apprenticeship period, partly because the productive contributions of apprenticeship graduates were worth more than their wages at the time and partly because of lower recruitment and training costs [2].

A study of 60 employers in Australia in 1998–1999 found that net costs over a four-year apprenticeship were nearly 1.4 times the benefits [9]. However, net costs declined sharply over time: By the fourth year, the benefits exceeded costs. Although this analysis did not estimate the post-apprenticeship benefits that accrued to employers, the trend in productivity growth suggests that employers might have reached a break-even point by the sixth or seventh year, after factoring in reduced recruitment and training costs.

In summary, studies of the net costs to firms during the apprenticeship period indicate wide variations across countries, occupations, and time. Central to firms’ ability to recoup most or all of their training costs is the amount of time apprentices spend in directly productive activities. Swiss firms are particularly effective at combining major investments in apprenticeship training with extensive use of apprentices in production. Given such low net costs (or even small net benefits), apprenticeships can be valuable to firms even if they retain only half or fewer of the graduates. As a result, most firms view their investments in apprenticeship programs as critical to their long-term success in producing high-quality goods and services.

Estimating the post-training benefits of apprenticeships

The post-training benefits of apprenticeship programs are especially important, but they are not easy to quantify. They include:

reduced recruitment costs;

training related to the company’s specific procedures; and

enhanced wage stability (because outside hires can upset the relative wage balance).

Firms report that another advantage of apprenticeships is the “option value” of having extra well-trained workers. In a world of uncertainty about levels of production and irreversible investments in certain workers, firms that invest in apprenticeship training create “real options.” When workers complete their training, firms have the option—but not the obligation—to hire some or all of the trained workers. Having additional well-trained workers with a range of skills allows firms to deal with unexpected increases in demand or losses of other experienced workers. Although difficult to quantify, the value of these options raises a firm’s return on apprenticeship investments.

A survey of German employers offers some insight into post-program benefits [10]. Savings in recruitment and training costs averaged nearly €6,000 for each skilled worker trained in an apprenticeship and taken on permanently. Other benefits include reduced errors in placing employees, avoiding excessive costs when the demand for skilled workers cannot be quickly filled, and performance advantages favoring internally trained workers who understand company processes over skilled workers recruited from the job market. Taking all of these benefits into account appears to make apprenticeship investments a net gain for employers [2].

Another benefit to firms rarely captured in studies is the positive impact of apprenticeships on innovation. Innovations are critical to success in a competitive environment. Well-trained workers are more likely to understand the complexities of a firm’s production processes, and therefore identify and implement technological improvements, especially incremental innovations to improve existing products and processes. A study of German establishments documented this connection and found a clear relationship between the extent of in-company training and subsequent innovation [11].

Reports by apprenticeship-sponsoring firms are revealing, even if they do not provide rigorous evidence of economic returns. In the US, evidence from surveys of more than 900 employers indicates that the overwhelming majority of them believe their programs are valuable and involve net gains [12]. Nearly all sponsors reported that the apprenticeship program helps them meet their skill demands. Other benefits of apprenticeships include reliably documenting appropriate skills, raising worker productivity, increasing worker morale, and reducing safety problems. Only 5–8% of surveyed firms did not find these benefits of apprenticeships to be important.

Nearly 87% of sponsors reported that they would strongly recommend registered apprenticeships, and another 11% would recommend apprenticeships with some reservations. Only 2–3% said they would not recommend apprenticeships. Surprisingly, only one in four employers regarded “poaching”—in which non-training firms hire apprentice graduates away from the firms that trained them—as a serious problem. Even among the firms most concerned about poaching, 85% still highly recommend apprenticeships.

Employer expressions of support for apprenticeships are therefore quite common. Especially striking are the positive attitudes of employers that have recently adopted apprenticeship training programs. England and Wales are particularly interesting in this regard because of the large increase in the number of firms there that now offer apprenticeships (well over 100,000). A study of more than 4,000 employers found that nearly 80% were satisfied with their apprenticeship program, while only 6% were dissatisfied.

Nearly three in four employers mentioned improved productivity as a primary benefit, with most highlighting other outcomes likely to improve profitability, product, or service improvements; better staff retention; and the introduction of new ideas and innovations. More than 40% of employers reported that apprenticeships helped them win new business. About 80% of employers reported that they expect to continue offering apprenticeships, and another 11% are considering doing so but are not certain.

Accounting practices and gains from apprenticeships

Managers often assert that the skills and commitment of their employees are their companies’ most valuable assets. At the same time, they say that they can only manage what they can measure [13]. Because human capital investments are not treated the same as physical investments on company balance sheets, managers may underestimate the gains from investing in apprenticeships. All of the spending on skill development is a cost in the current year, although the company will potentially gain benefits from these expenses over several years [13].

If investments in training were treated more closely in line with economic reality for measuring profits and assets (but not for tax purposes), the contributions of these investments would be measured more precisely and the benefits would become more apparent [13]. Training investments should count as assets only to the extent that they yield a flow of future benefits to the company. The fact that companies are currently willing to finance an extensive amount of training is almost certainly an indication of their ability to capture some of the gains [13].

Limitations and gaps

Many firms are able to recoup most or all of the gross costs of apprenticeship training during the training period itself. Providing occupational training that is valuable outside the firm appears inconsistent with human capital theory’s expectation that firms will pay only for specific training valuable to that firm. However, because firms recoup most of the investment within the training period, the net costs of this general training are often low, if not zero. Firms that make positive net investments capture their returns in the early post-apprenticeship period.

The quantitative estimates and qualitative reports come from employers that train or have trained apprentices. Whether these returns on apprenticeship investments would apply to firms not currently undertaking apprenticeship training is an open question. A demonstration that randomly encourages some but not other firms to use apprenticeship training would help answer that question. Other evidence can be garnered from countries in which substantial numbers of firms have recently adopted apprenticeships.

Summary and policy advice

Countries with robust apprenticeship systems are showing by example how education and training can keep youth unemployment low and enhance the quality of jobs that do not require baccalaureate degrees. International organizations are increasingly calling on other countries to expand apprenticeship programs. But will enough employers find it in their interest to offer such programs? A common argument is that by not offering apprenticeships, firms are signaling that they do not view them as economically beneficial.

Alternatively, employers may simply lack institutional support and knowledge about how apprenticeship programs can increase profitability. After all, in countries with major initiatives to help firms understand and start programs (such as Australia and England), apprenticeship programs have expanded rapidly.

Since apprenticeship training is highly effective for workers and yields external benefits that cannot be captured by the firm, it makes sense to use public resources to stimulate apprenticeships. In many countries, reallocating funding from school-based vocational programs to apprenticeship programs that emphasize work-based learning can lower the costs per worker and increase the quality and relevance of training.

While an international consensus favors expanding apprenticeships, the major policy question is this: How can countries develop and sustain large-scale apprenticeship training? Attracting workers to take advantage of existing apprenticeship opportunities is rarely a serious problem. So the question becomes: How can policies stimulate employers to increase the overall number of apprenticeships?

In countries with limited programs, government and industry leaders need to campaign at the local and national level to encourage public support for apprenticeship programs. Success requires an effective “retail” sales and technical support effort. Staff of the government office or the intermediary organization that is marketing apprenticeship must convince firms that apprenticeships are good for business and must teach most businesses how to build an apprenticeship program. Once employers begin to adopt apprenticeship, they will likely continue to do so, thereby providing post-secondary training and education at a modest cost.

England’s recent success in expanding apprenticeships demonstrates the feasibility of this approach. Apprenticeship starts jumped to more than 500,000 by 2012–2013, a fivefold increase from 1999 levels and more than double those of 2007. In England, apprenticeship is becoming a mainstream option for workers and a common practice for firms. In the US, South Carolina’s Apprenticeship Carolina initiative has also succeeded, being marketed at the state and individual firm levels, helped along by a small tax credit. Since 2007, South Carolina companies using apprenticeship increased from 90 to over 660, even as the Great Recession led to job losses between 2007 and 2012.

Acknowledgments

The author thanks an anonymous referee and the IZA World of Labor editors for many helpful suggestions on earlier drafts. Financial support from the Smith Richardson Foundation is gratefully acknowledged. This article is partly based on [2].

Competing interests

The IZA World of Labor project is committed to the IZA Guiding Principles of Research Integrity. The author declares to have observed these principles.

© Robert Lerman